Double glazed glass

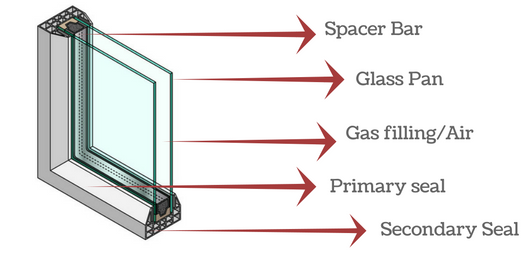

Double glazed glass consists of two layers of glass and their spacing is usually between 6 and 20 mm. The gap between the two glass layers is filled with an aluminum spacer. Spacer is a continuous hollow frame used to separate two pieces of glass in double glazed windows. Aluminum spacers are light, flexible and very strong. In order to absorb moisture and prevent vapor on the glass, the spacer interior is filled with a hygroscopic material (silica gel). The gap between the two pieces of glass is filled with argon gas. This method is also called double glazing insulation, because the ability of air to pass between the glasses results in a significant reduction of heat and sound transfer, and finally, it is insulated with two-component silicon sealant.

The Almas Shishe Jahan Nama Company uses a structural silicon sealant as a secondary adhesive to enhance the quality and efficiency of its double-glazed glass and perfect sealing of the glass. This adhesive is manufactured according to ASTM C 1184 standard and has a high resistance to UV light, high temperature and environmental degradation. This kind of adhesive has allowed Almas Shishe Jahan Nama Company to fully guarantee the durability of insulation of its double-glazed windows for 15 years.

The company also embeds the silica gel with a vacuum device inside the spacer to prevent exposure to air. The presence of a dehumidifier exposed to the air will result in the loss of its dehumidifying ability and thus the formation of water vapor among the walls.

Advantages of argon gas in double glazed glass

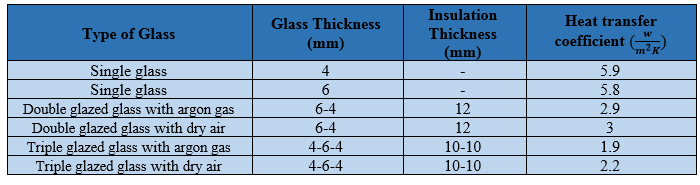

The speed of sound transmission in air and argon gas is 350 and 320 m / s, respectively. Therefore, the injection of argon gas into a double-glazed glass reduces the speed of sound and noise pollution. The quality of double-glazed glass that is filled with argon will not change until the concentration of argon gas reaches 75%. Therefore, a double glazed glass filled with argon gas will have a good conductivity for at least 20 years.

The amount of argon gas injected in the space between the two layers of glass should be a certain amount to maintain its performance. In the Almas Shishe Jahan Nama Company, the amount of argon gas injection is based on the size of the glass so that the dimensions of the glass are given to a specific machine and the amount of argon required is determined.